|

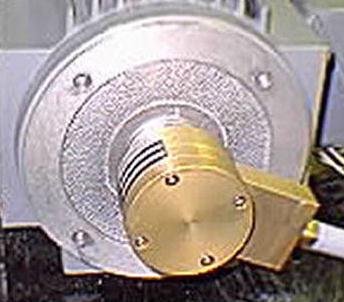

CC340T DIGITAL PULSE TACHOMETER |

|

The CC340T Pulse Tachometer is a shaft mounted design for mill applications requiring a rugged, low cost and precision design. APPLICATION

|

|

Code |

- Incremental, Optical |

|

Cycles per Revolution |

- Code Disc: 120, 240, 256, 270, 300, 500, 512, 540, 600, 1000, 1024, 1200, 2048 |

|

Supply Voltage |

12 -15 VDC +/-5% or 20 -30 VDC |

|

Supply Current (8830) |

- CMOS + 150 mA max, 125 mA, typical |

|

Output Signal |

- Square wave, with following: |

|

Output Voltage |

- 5 VDC to 30 VDC |

|

OA to OB Transition |

- 15% Minimum Separation |

|

Pulse to Any Pulse Accuracy |

- +/-2 Minute of ARC (RMS) |

|

Pulse to Adjacent Pulse |

- +/-0.5 Minute of ARC |

|

Temperature |

- Operating, -40 o C to 100o C |

|

Velocity Range |

- 0 to 30,000 RPM |

|

Speed Response |

- Down to 0 RPM |

|

Output Protection |

- Power Supply Reversal |

|

Housing |

- NEMA 13 - Material: 6061 Aluminum, Anodized - Seal: O-Ring |

|

Fasteners |

- 303 Stainless Steel |

|

Shaft Size |

- 0.6250” (+.0000, -.0005) 303 Stainless Steel |

|

Moment of Inertia |

- 55 gm/cm 2 |

|

Bearing Life |

- 2 x 10 8 revs at Rated Shaft Loading |

|

Shaft Torque |

- 0.5 to 1.0 oz.-in., Without Seal |

|

Shaft Run out |

- 1.0 to 2.0 oz.-in. With Shaft Seal |

|

Shock |

- 50 G’s for 11msec Duration |

|

Vibration |

- 5 to 2000 Hz @ 20 G’s |

|

Weight |

- 3 lb. |

HOW TO SPECIFY

DIGITAL PULSE TACHOMETER

Example:

| CC340T | 1024 | ABZ | 12 | 10A | EN1 | or | M12 | or | C5 |

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

CC340T = BASIC (Mill Duty) Design 1 = OUTPUT DESIGN 2 = CYCLES PER REVOLUTION 3 = OUTPUT SIGNAL 4 = OUTPUT VOLTAGE 5 = OUTPUT TERMINATION MOUNTING SPECIFICATION GUIDE TAPPED MACHINE CENTER HOLE MOUNTING 6 = SHAFT ADAPTER ________EN1 = 1.125" dia shaft adapter

with machine shaft 3/8, 1/2, 5/8, M10, M12, or M16 tapped

center hole MM = millimeters ________MM1 = 25mm shaft with machine shaft 3/8, 1/2, 5/8, M10,

M12, or M16 tapped center hole TAPPED CENTER HOLE 7 = MOUNTING HARDWARE

All hardware supplied with locking nylon insert. 8 = PRESSURE CLAMP MOUNTING ________C1 = 1.000" dia shaft with pressure

clamp mounting

|

PRODUCT DIMENSIONS

Dimensions = Inches

(mm)